www.PETequip.netYour source for used PET processing machinery and other plastic processing and packaging equipment

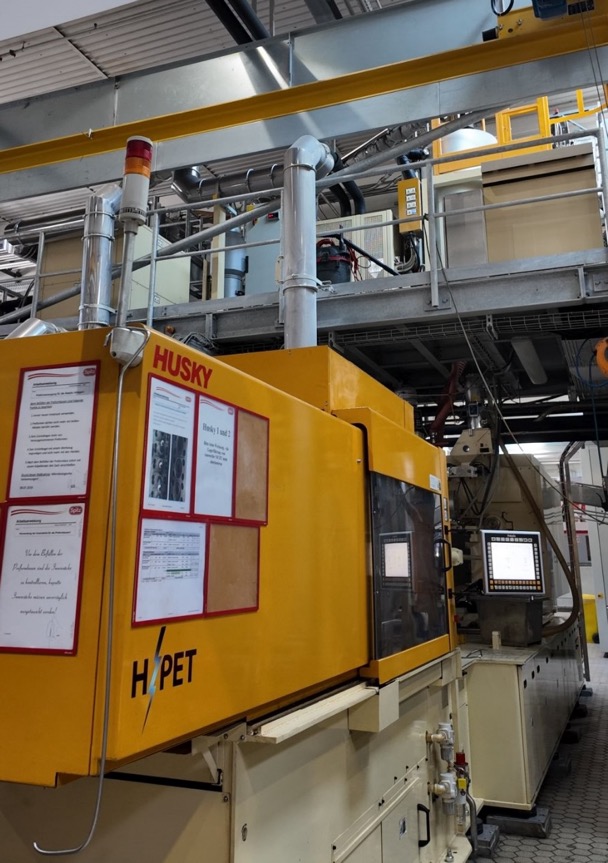

ITEM # : PIMS023 & PIMS024

Make : Husky

Model : H-PET 230 AE RS95 Fully Electric (Download Machine Brochure by clicking here)

Qty. : 2

Delivered in : Dec-2015

Installed in : Feb-2016

Includes Moulds, Resin Dryer, Hopper, Loader, Mould Dehumidifier, Preform Conveyor. Also included Mixing unit for solid colours + Mixing unit for liquid colours.

Maximum Throughput : 390 kg/ hr

Maximum Shot Size : 2,424 gm PET

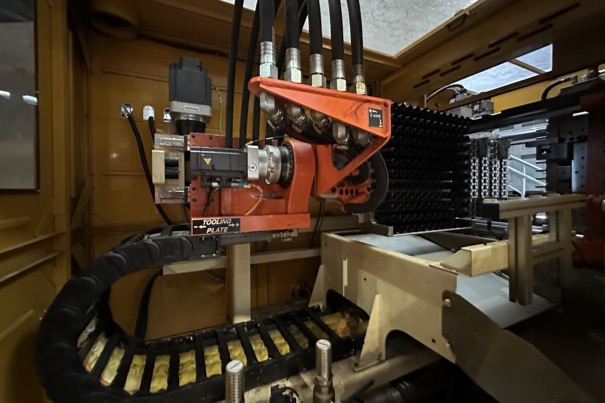

Post Mixing Devise in Machine Nozzle

Auxiliaries Controlled through Machine's HMI

Chilled Water Pressure, Flow Rate & Temperature indicated in HMI

Automatic Lubrication System

Resin Dryer from Husky : Model DR815HT-G3 with 4,000 L stainless steel hopper. Includes level control, air flow speeds and dew point based regeneration.

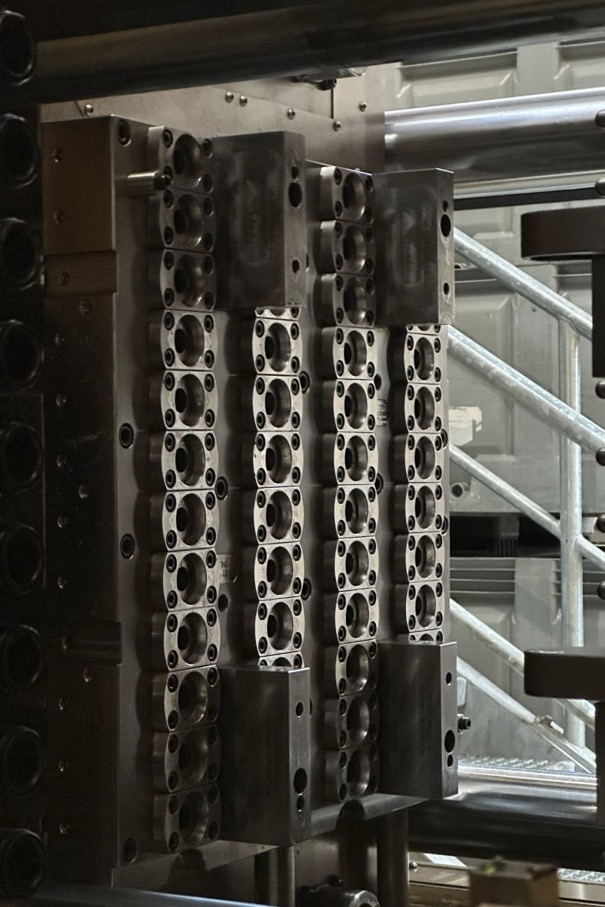

Machine 1 (PIMS023) is with 32 cavity 63.5 mm x 140 mm pitch mould

32 cavity Mould 1 : 38 mm Bericap 18 gm. Cycle time : 11.3 sec. Output : 10,200 PPH. Click here to open preform drawing.

32 cavity Mould 2 : 38 mm Bericap 29 gm. Cycle time : 13.7 sec. Output : 8,400 PPH. Click here to open preform drawing.

Machine 2 (PIMS024) is with 48 cavity 50 mm x 140 mm pitch mould

48 cavity Mould 1 : PCO1881 17.8 gm. Cycle time : 12.4 sec. Output : 13,935 PPH. Click here to open preform drawing.

48 cavity Mould 2 : PCO1881 27.8 gm. Cycle time : 15 sec. Output : 11,520 PPH. Click here to open preform drawing.

You may view videos here-

https://youtu.be/_z7s1ryHC6I

https://youtu.be/4wAlFW4cVgg

https://youtu.be/kYyiAVcJYAs

https://youtu.be/S5e4hYwi76w