www.PETequip.netYour source for used PET processing machinery and other plastic processing and packaging equipment

BOTTLED WATER PLANT, INCLUDING PACKING OF 20L/ 5 GALLON BOTTLES AND POUCHES (Installed in 1998)/ Mint condition and used sparingly

1) Rinsing, filler & capping line (120 BPM up to 2L)

2) Conveyor

3) Labeler

4) Ink-Jet Printer

5) Pouch filling machine

6) 20L x 450 Jars/ hour automatic rinsing, filling and capping line (Made in USA) : auto loading, brushing, 6 stage rinsing with detergent and hot water as well as ozonized water, filling and capping line

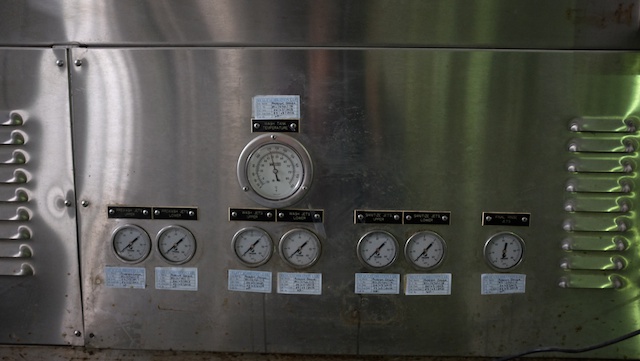

7) Water Processing-

Multimedia Filtration : to remove suspended particles

Softening ION Exchange : Minerals imparting hardness to water are removed

Reverse Osmosis : All impurities toxic elements minerals and micro–organism including viruses are removed

Chlorine Injection : to minimize microbial contamination by killing micro-organism

Granular Activated Carbon Filtration : to remove color, odor and chlorine

Re-mineralization : adds requisite quantity of mineral salts required for body metabolism and taste to water

Absolute filtration : final process for purity and crystal clear water quality

Ultraviolet Sterilization : to minimize microbial contamination by killing micro–organism

Ozonization : to maintain sterility of water during and after the process

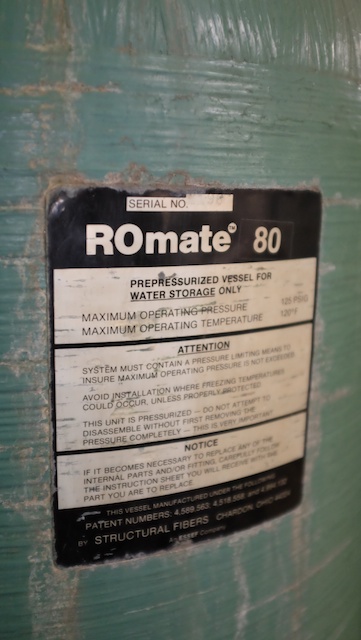

8) 2 x 30 kL Storage Tanks